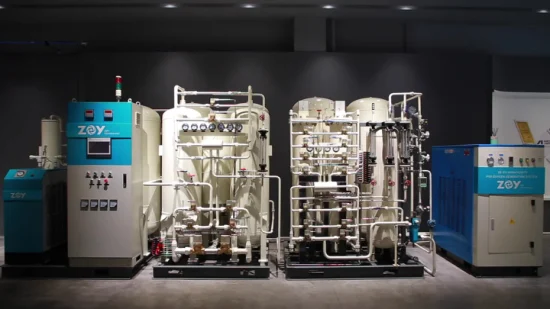

Oxygen Generator Psa Filling Production Plant India Cost for Sale

Oxygen Generator PSA Filling Production Plant India Cost for Sale Cape-Golden PSA Oxygen Plant India Systems offer an en

Description

Basic Info

| Model NO. | CAOG-40 |

| Flow Rate | 2m3/H to 300m3/H |

| Technology | Pressure Swing Adsorption (Psa) |

| Material | Carbon Steel |

| Type | Skid Mounted |

| Dimension | 220*130*180cm |

| Weight | 2100kg |

| Service Life | Over 10 Years |

| Transport Package | Wooden Case |

| Specification | CAOG-40 |

| Trademark | Cape-Golden |

| Origin | China |

| HS Code | 8419601900 |

| Production Capacity | 100 |

Product Description

Oxygen Generator PSA Filling Production Plant India Cost for Sale Cape-Golden PSA Oxygen Plant India Systems offer an endless supply of Oxygen for a wide range of commercial applications For more than 10 years, Cape-Golden has manufactured Oxygen Plant India in purities from 90% to 99%. Our rugged and reliable Oxygen Plant India are precision-tuned and ideally suited for a range of commercial applications.

How does Cape-Golden's PSA Oxygen Generator Work?

Ad-sorption is the physical process of separating molecules. Our Pressure Swing Adsorption (PSA) oxygen generation systems generate oxygen by separating it from the nitrogen in ordinary air. Air is 20.9% oxygen and 79% nitrogen, along with a small percentage of inert gases.Within our Oxygen Plant India, a vessel containing a molecular sieve called zeolite is filled with compressed air. The nitrogen molecules are adsorbed by the sieve material while the oxygen molecules drift past and are collected in an oxygen receiver tank attached to the oxygen generator.Pressure is then released from the vessel, and the nitrogen molecules are vented to the atmosphere. While the depressurization is occurring, the cycle is repeated in a second vessel. The process is repeated swinging from one vessel to another for as long as there is an oxygen demand.

Features

• All components are oxygen-compatible• Produce oxygen from compressed air• Microprocessor controlled• Low operating cost• Automatic and unattended operation• Easy to install and maintain

Applications in Chemical Engineering

In the process of chemical production, we can use oxygen instead of ordinary air to improve the output and quality of products. Dozens of chemical products, such as carbon black, formaldehyde, can be produced with oxygen enrichment.The main application of oxygen in chemical engineering is to enhance production. For example, oxygen for organic chemicals, oxygen for acid production, pulp oxygen bleaching, oxygenated high-pressure gasification of gas, oxygenation of poor coal fields, production of petroleum protein with oxygen, manufacturing of fuel cells, cracking of crude oil, production of natural gas instead of gas, rock crushing by flame injection, Kraus sulfur recovery, and so on.Take hydrogen peroxide production process for example, using oxygen enrichment as molecular oxygen source, not only improves the hydrogen peroxide production device, and due to the increase of oxidation reaction rate from hydrogen peroxide production process of tail gas treatment plant of exhaust quantity reduced, aromatic hydrocarbons emissions also reduce accordingly, reduce the pollution to the environment, and economic benefit of double effect is obtained.

| PSA Oxygen Generator | ||

| Capacity (Nm³/h) | Purity(%) | Model |

| 1 | 93~99 | CAOG-1 |

| 2 | 93~99 | CAOG-2 |

| 4 | 93~99 | CAOG-4 |

| 5 | 93~99 | CAOG-5 |

| 6 | 93~99 | CAOG-6 |

| 8 | 93~99 | CAOG-8 |

| 10 | 93~99 | CAOG-10 |

| 15 | 93~99 | CAOG-15 |

| 20 | 93~99 | CAOG-20 |

| 25 | 93~99 | CAOG-25 |

| 30 | 93~99 | CAOG-30 |

| 40 | 93~99 | CAOG-40 |

| 50 | 93~95 | CAOG-50 |

| 60 | 93~95 | CAOG-60 |

| 100 | 93~95 | CAOG-100 |

| 200 | 93~95 | CAOG-200 |

| CA® PSA Oxygen Generator for Filling Cylinders | ||

| Qty of cylinders (pieces/day) | Purity(%) | Model |

| 12 | 93~99 | CAFS-3 |

| 20 | 93~99 | CAFS-5 |

| 40 | 93~99 | CAFS-10 |

| 60 | 93~99 | CAFS-15 |

| 80 | 93~99 | CAFS-20 |

| 100 | 93~99 | CAFS-25 |

| 120 | 93~99 | CAFS-30 |

| 200 | 93~99 | CAFS-50 |

| 320 | 93~99 | CAFS-80 |

| 400 | 93~99 | CAFS-100 |

| Remark: Cylinders capacity is 6m3 | ||

| For more details , pls feel free to contract with us. | ||

Prev: Skid-Mounted Medical Hospital Use Psa Oxigen Producing Machine Oxygen Cylinder Filling Plant Price

Next: Highly Efficient Hot Sale Medical Psa Oxigen Oxygen Plant for Cylinder Filling with Buffer Tanks

Our Contact

Send now